Author: Izaz Ul Islam

1. Introduction: The Sludge Management Challenge

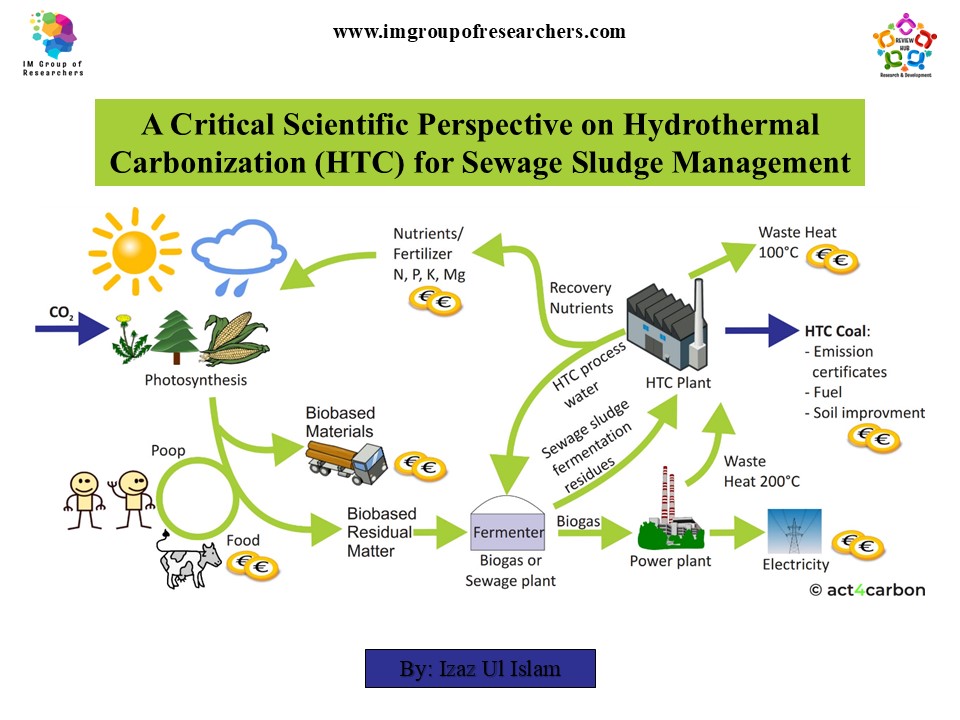

Sewage sludge management remains one of the most complex and costly challenges in municipal and industrial wastewater treatment. Globally, wastewater treatment plants generate millions of tons of sludge annually, containing high moisture content, pathogenic organisms, organic pollutants, nutrients, and potentially toxic heavy metals. Conventional disposal routes—land application, incineration, composting, or landfill—are increasingly constrained by tightening regulations, public opposition, rising costs, and environmental risks.

Against this backdrop, Hydrothermal Carbonization (HTC) has emerged as a promising thermochemical pathway that transforms wet organic residues into a carbon-rich solid known as hydrochar, while avoiding the energy-intensive drying required by traditional thermal processes. In recent years, HTC has progressed from laboratory studies to full-scale demonstration, with integrated solutions such as the HBI sewage sludge treatment concept in Italy signaling technological and commercial maturity.

2. Fundamentals of Hydrothermal Carbonization

HTC is a thermochemical process conducted in hot compressed water, typically at 180–250 °C and autogenous pressures (2–6 MPa). Under these conditions, water acts simultaneously as:

- A reaction medium

- A reactant

- A catalyst

The process induces dehydration, decarboxylation, hydrolysis, and polymerization reactions, converting biomass into:

- Hydrochar (solid fraction)

- Process water (liquid fraction rich in dissolved organics)

- Minor gaseous products (mainly CO₂)

For sewage sludge, HTC offers a unique advantage: it is inherently designed for high-moisture feedstocks, eliminating one of the biggest energy penalties in sludge treatment.

3. Heavy Metal Immobilization: A Key Environmental Advantage

One of the most critical scientific advantages of HTC is its impact on heavy metal stabilization. Sewage sludge often contains metals such as Cd, Pb, Cu, Zn, Ni, and Cr, which limit reuse options.

Multiple studies report that HTC:

- Transfers heavy metals preferentially into the solid hydrochar fraction

- Converts metals into less bioavailable and more stable mineral or organo-metallic forms

- Reduces leaching potential under environmentally relevant conditions

Mechanistically, this immobilization occurs due to:

- Complexation with oxygen-containing functional groups on hydrochar

- Encapsulation within newly formed carbon matrices

- Association with mineral phases generated during HTC

However, HTC alone does not eliminate heavy metals; it redistributes and stabilizes them. This limitation underscores the importance of post-HTC separation and treatment strategies, an area where HBI’s patented technology provides a critical advancement.

4. From HTC to Integrated Energy Recovery: Beyond Standalone Processes

While HTC significantly improves sludge dewaterability, volume reduction, and pathogen destruction, early criticism of the technology focused on:

- Moderate energy density of hydrochar compared to fossil fuels

- High organic load in HTC process water

- Limited net energy recovery if used as a standalone solution

HBI’s approach addresses these limitations through system integration, notably by coupling HTC with downstream gasification.

Key Innovations in the HBI Concept:

- Gasification of hydrochar to achieve complete energy recovery

- Thermal self-sufficiency of the entire system

- Recovery of nutrients while isolating hazardous metals

- Closed-loop heat and material integration

From a systems engineering perspective, this transforms HTC from a pretreatment technology into a core platform for circular resource recovery.

5. Process Water Valorization and Biogas Enhancement

HTC process water is often viewed as a challenge due to its high concentration of:

- Dissolved organic carbon

- Short-chain organic acids

- Nitrogen compounds

Rather than treating this stream as waste, HBI’s concept aligns with emerging research demonstrating that HTC liquor can serve as a highly effective co-substrate for anaerobic digestion.

Peer-reviewed studies report:

- Increased methane yields (up to 30–50%) when HTC process water is co-digested

- Improved carbon utilization efficiency

- Enhanced overall energy balance of wastewater treatment plants

This integration closes the carbon loop, converting what was previously a problematic effluent into a biogas-boosting resource.

6. Environmental and Economic Performance: A Critical Assessment

Environmental Benefits

- Significant sludge volume reduction

- Pathogen elimination

- Reduced greenhouse gas emissions compared to landfilling or incineration

- Lower risk of soil and groundwater contamination

Economic Advantages

- Reduced disposal and transport costs

- Energy self-sufficiency

- Potential revenue from energy and recovered materials

- Improved compliance with tightening regulations

However, critical challenges remain:

- Capital costs are still higher than conventional treatments

- Long-term stability and regulatory acceptance of hydrochar reuse vary by region

- Process optimization is required for different sludge compositions

HBI’s success suggests that economic viability depends on integration, not HTC in isolation.

7. Implications for the Circular Economy

From a circular economy perspective, integrated HTC systems represent a paradigm shift:

- Waste is converted into energy carriers

- Nutrients are recovered rather than destroyed

- Harmful substances are isolated and managed safely

- Residual streams are reintegrated into existing infrastructure

This aligns closely with EU waste hierarchy principles and emerging sustainability frameworks that prioritize resource recovery over disposal.

8. Market Readiness and Investor Confidence

The recent €15 million Series A funding round secured by HBI provides a strong signal that hydrothermal sludge treatment has crossed a critical threshold—from experimental technology to bankable infrastructure solution.

Investor interest reflects:

- Regulatory pressure on sludge disposal

- Rising energy prices

- Demand for decentralized, resilient waste-to-energy systems

9. Conclusions and Outlook

Hydrothermal Carbonization has matured from a promising laboratory concept into a strategic enabling technology for sustainable sludge management. Yet, its true potential is realized only when embedded in integrated treatment and energy recovery systems, as demonstrated by HBI’s market-ready solution.

By addressing heavy metal immobilization, energy efficiency, nutrient recovery, and carbon reuse in a single platform, advanced HTC systems pave the way for:

- Climate-neutral wastewater treatment plants

- Reduced environmental liabilities

- A genuinely circular sludge economy

As regulatory support strengthens and industrial adoption accelerates, HTC-based solutions are poised to play a central role in the future of municipal and industrial wastewater management.

Read More: A New Era for Carbon Removal

Follow Us on